How to do it?: Quick guide to a preventive maintenance plan in Excel

The preventive maintenance plan is a job that you can track in Excel. It is essential to do this traceability, since you will know which equipment or assets you need to repair or maintain.

ButWhat does a preventive maintenance plan consist of?

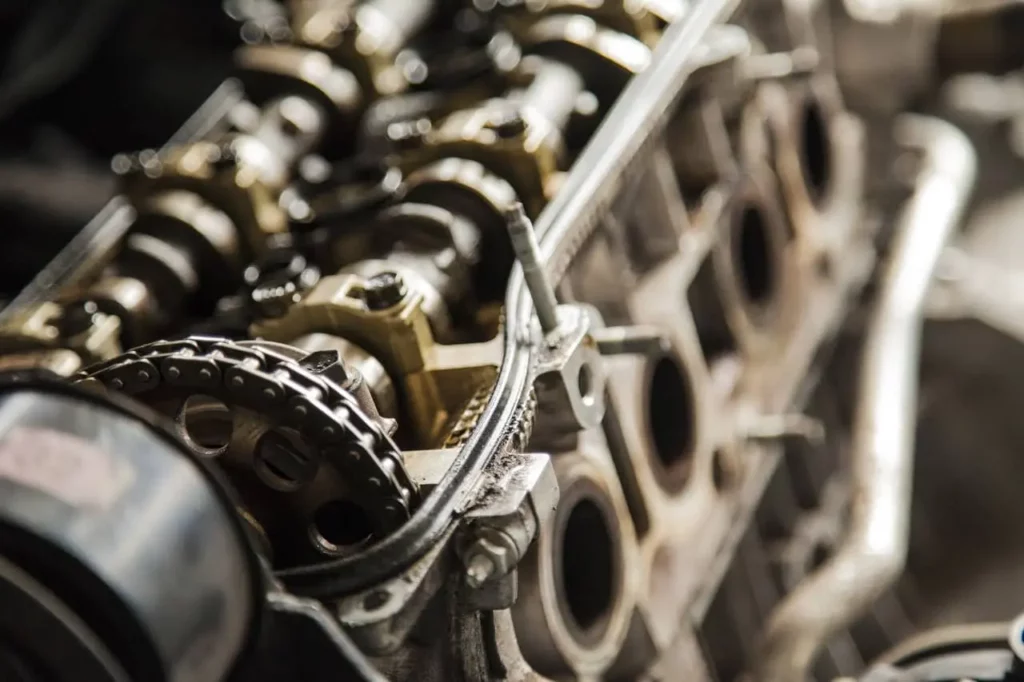

In simple terms, they are inspections that are carried out from routine and scheduled tasks to the equipment or assets of a company. In this way, the possibility of a certain piece of equipment failing is minimized.

Some examples: lubrication, chain or belt adjustments, technical inspections, etc. made by the manufacturer.

According to Fiix Software, the objectives are: increase asset reliability, reduce downtime, and maximize cost and labor impact.

To consider:

Preventive maintenance is activated based on time or usage. For example, if an asset has operated for 100 hours, a preventative maintenance work order will be automatically activated.

Did you know that you can implement a preventive maintenance plan in Excel? Keep reading this blog and you will know the step by step to do it.

What is the importance of creating a preventive maintenance plan?

Creating a preventive maintenance plan is essential for proper production operation. Thus, by having a periodic control, you avoid breakage problems and improve safety. In fact, as cited by MaintainX, preventive maintenance can save facilities up to 18% in maintenance costs.

But why is it important to make a preventive maintenance plan in Excel? You will be able to tell if there is a reduction in unplanned downtime, buildup, miscommunication, accidents, and corrective maintenance costs associated with each.

In short: making a good preventive maintenance plan will help you overcome inefficiency.

What should a company's maintenance sheets include in Excel?

To make a company maintenance spreadsheet in Excel, you must consider the following variables. The information is collected from Sofeast and JustExw:

- Installation of the machine or asset. If it is not the installation itself, make a record of the control of that machine or asset.

- Tasks associated with that installation or maintenance control.

- Agreed frequency to carry out the review or installation (daily, weekly or monthly)

- Parameters that should be used to control, specifications and materials that are needed.

- The tests to run.

- Periodicity of reviews.

- Frequency of reports.

How to make a preventive maintenance plan in Excel?

If the purpose is to make a preventive maintenance plan in Excel, a series of variables must be considered. Depending on the type of maintenance to be done, such variables may change.

However, below we leave some important points when creating a maintenance plan in Excel. Let's review!

Define goals and objectives

The first step in establishing a preventive maintenance plan in Excel is to define what needs to be accomplished. Do I need to save money on maintenance? Should I avoid failures that could compromise the operation of the company? Maintain expensive equipment that is difficult to replace?

OK with BRR, you must be concrete and establish specific and achievable goals.

An example: Increase machine availability with 50% or Reduce failures with 80%.

Make table with inventory of assets

When you take an inventory, you will have a clear picture of the equipment you need to maintain. What factors should I consider? We give you some ideas from Infraspeak.

- Warranty periods.

- Manufacturer's recommendations or user manual for equipment maintenance. Example: maintenance frequency, expected useful life, optimal temperature and humidity conditions, etc.

- Information from previous controls to verify the operation of the equipment.

- Data from previous repairs.

- Asset Criticality

- Legal requirements.

Assign priorities and resources

With this data already entered, it is time to assign the tasks to the responsible people. At this point, it is recommended to add a priority (low, normal or high) and a due date to ensure the entire team is aligned.

In fact, it is advisable to previously check the machinery and/or assets for maintenance. By having this record, instructions for maintenance must be given. For example, the necessary spare parts, consumables, documents, tools, safety regulations, etc. can be listed.

Create maintenance indicators

It's difficult to know if a preventive maintenance program in Excel is working without setting concrete goals. There are many maintenance metrics you can use.

According to FixSoftware, some of them may be:

- Critical percentage of scheduled maintenance.

- Planned maintenance percentage.

- Compliance with preventive maintenance.

- The overall effectiveness of the team.

- Mean time between failures.

Define responsible

It is important to establish resources, time, labor, and other requirements for each preventive maintenance task. This allows managers to easily assign tasks to those responsible. All of this, depending on the skill set and availability of a technician.

From GofMx, suggest “having each maintenance technician perform a preventive maintenance task is an excellent way to gauge their understanding of the process.”

Review and improve the preventive maintenance plan

It's essential to have a preventive maintenance checklist. This way, you'll constantly track KPIs, such as mean time to repair, percentage of planned maintenance, and mean time between failures.

Analyzing these statistics and comparing them to the numbers from the previous plan should give you a good idea of how your program is affecting the efficiency of your maintenance operation.

Related questions

Time-based preventative maintenance: It is done at established time intervals. According to recommendations, it is most beneficial for equipment that needs maintenance according to a schedule.

Meter-Based Preventative Maintenance: Performed from an established meter reading. Preventive maintenance tasks are activated after a certain number of hours operated, kilometers traveled or production cycles completed.

In accordance with maintworld, these are the main maintenance indicators.

Planned maintenance percentage (PMP): Percentage of time spent on planned versus unplanned maintenance activities.

General Equipment Effectiveness (EGE): Measurement of the productivity of a piece of equipment. Provides informed data on the effectiveness of maintenance processes based on factors. Some of them are: the quality, performance and availability of the equipment.

Mean Time to Repair (TMR): It is the measure of the maintainability of repairable elements. This includes repair time, testing period and return to normal operating condition.

mean time between failures (TMEF): It is the measure of the expected time between one breakdown and the next during normal operation.

Compliance with preventive maintenance (CMP): Preventive maintenance compliance is defined as the percentage of preventive work scheduled and completed in a given time.

It is a list with all the actions to be carried out in the preventive maintenance plan in Excel. A maintenance checklist is used to:

1- Constant monitoring of KPIs.

2- As the average repair time.

3- Percentage of planned maintenance.

4- Average time between failures.